Latest News

- Hyundai E&C Becomes Key Player in the Nuclear Decommissioning Market

- Hyundai E&C Accelerates Global Nuclear Expansion into the U.S. Nuclear Market

- Hyundai E&C Shifts into High Gear to Enter Nordic Large-Scale Nuclear Market

- Hyundai E&C Strengthens Korea-Japan Cooperation in Energy Transition and New Growth Businesses

- Hyundai E&C Signals Green Light for Large-Scale Nuclear Power Plant Business in Europe

[Technology that is strong against climate] “How is it that buildings that can withstand even high winds are constructed?”

‘Clawing through’ is a staple expression that is used in news about typhoons that spread to various parts of the world. Stories about strong winds or typhoons destroying glass windows and exteriors of buildings are common, and we also frequently hear stories about how strong winds instantly blow away moving cars and break down concrete structures. Typhoons refer to tropical cyclones in which the maximum wind speed at the center is greater than 17m/s, generated in the northwestern pacific. Typhoons are usually observed in between July and August, and on annual average, there are around 3.1 typhoons that affect Korea. According to the Korea Meteorological Administration, wind speed of 10m/s is strong enough to break the umbrella ribs, and at 15m/s, it would be difficult for people to walk. From 50 m/s, it is strong enough to destroy a house made of concrete. The strongest wind that was felt in the Korea Peninsula (Typhoon Maemi) had the maximum instantaneous wind speed of 60 m/s and this was strong enough to bend the transmission tower. Is there no technology that can go against the wind that is strong enough to wipe out everything? ‘Wind resistance design’ is the technology for constructing buildings and bridges that are structurally safe.

*’Typhoon’ would be referring to what is generated in the western part of the North Pacific along the waters, ‘Hurricane’ would be referring to what is generated in the eastern part of the North Pacific, the North Atlantic and the Caribbean Sea, and ‘Cyclone’ would be referring to what is generated in the Bay of Bengal and the Indian Ocean.

First ‘wind tunnel test lab’ in Korea for ‘wind resistance design’

The accident of the ‘Tacoma Narrows Bridge collapse’ that occurred in November 1940, in US, was an incident that sounded an alarm about the importance of wind resistance design. This was because bridge that was promoted with a proud title of being the third longest suspension bridge in the world collapsed in mere 4 months of being opened to the public. Tacoma Bridge was designed to withstand 53m/s, but at the time, the peripheral wind speed was only 19m/s. This was a huge shock to the global engineers. The cause of the collapse was not the intensity of the wind but the vibration generated through the wind. The top plate of the Tacoma Bridge became twisted because of the wind, and the bridge started to strongly lurch up and down. Vibration continued to exacerbate without stopping, and ultimately, the top plate collapsed, unable to bear the wind.

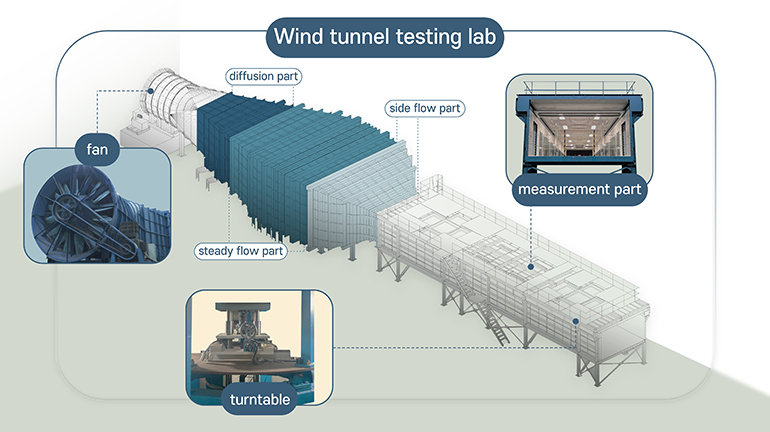

For the wind resistance design, comprehensive angles of the wind should be thoroughly analyzed. In addition, it is important to accurately measure the impact of the wind in line with the regional characteristics. Hyundai E&C constructed and is operating the wind tunnel testing lab that allows precise research on the impact of the wind for the first time in Korea since 1996. Wind Tunnel is a device in the shape of a tunnel for experimenting the impact that the wind has on buildings. Various wind resistance experiments are carried out here for building ranging from apartment buildings in the general form to high-rise buildings, office buildings with unstructured shapes, tower structures, structures with a large space and long span bridges.

Wind tunnel testing lab of Hyundai E&C consists of the ‘turntable’ that rotates the compressed model, which consists of the ‘Fan’ that generates the wind, ‘diffusion part’ that spreads the wind, ‘steady flow part’ that converts turbulence* into uniform flow*, ‘side flow part’ that raises the wind speed and ‘measurement part’ that measures the wind power and wind pressure, by 360 degrees.

*Turbulence: A phenomenon where air flows irregularly while generating small swirls due to friction with the ground or air.

*Uniform flow: A phenomenon where volume of air does not change over time. and flows steadily. Also known as 'steady flow'.

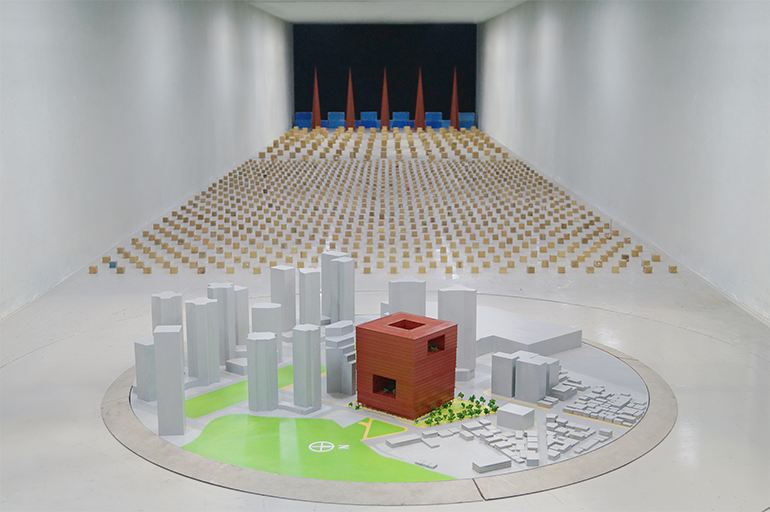

[Wind tunnel testing lab of Hyundai E&C. Fan that generates the wind, measurement part that measures the wind power and wind pressure, turntable that rotates the floor 360 degrees and so forth are installed]

Wind tunnel test is carried out on a manufactured model in a manner where the impact of the wind is analyzed in various angles by running the fan after installing the turntable that is placed at the entrance of the measurement part. Large wind tunnel of Hyundai E&C can generate wind that ranges from 0.3m/s to 17.5m/s. The intensity of the wind may seem weak, but according to the characteristic of the experiment that is carried out by making a model, the wind speed would amount to 100m/s or greater when converted to the intensity of the actual wind.

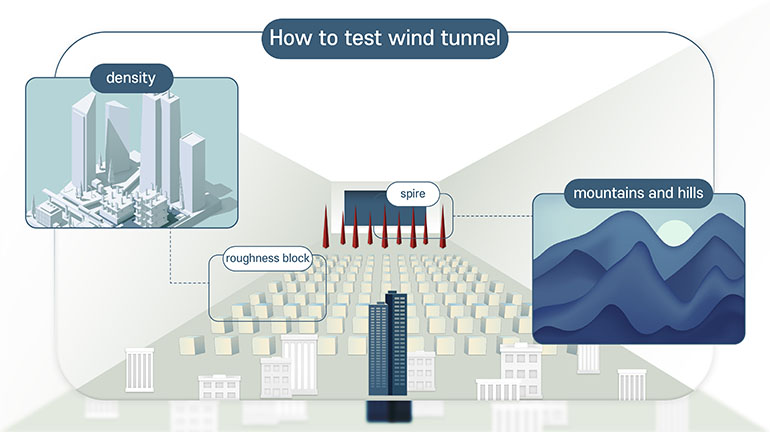

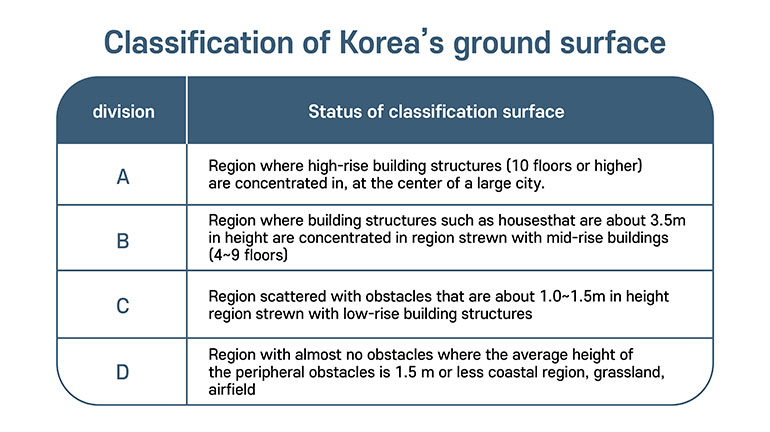

The experiment starts by ‘properly’ creating the wind. In Korea, there are four types of ground surfaces in large (※ Refer to below table). Wind blows more strongly when there are less structures. If one were to enter the wind tunnel testing lab of Hyundai E&C, Spire in the shape of a sharp and red pylon and a small wooden block, the Roughness Block catch the eyes. Spire represents the mountains and hills and the Roughness Block represents the density of the city. The number, size and the layout of Spires and Roughness Blocks are determined by the type of environment the experiment is subjected to. It is a precise task that takes more than 3 months for the initial setting alone. In addition, in nature, wind blows from everywhere. In the wind tunnel, turntable is rotated 360 degrees to extract and analyze the data while simulating the same condition as the nature.

Mission of the long span bridge, Beat the vibration of the wind!

Impact of the wind on the bridges is greater if the bridges are longer. Hyundai E&C conducts a wind resistance design through the wind tunnel testing lab for special long span bridges where the spans are longer than 200 m (distance between either towers) or when the ratio of width and length of span (span÷width) exceeds 30. The basis of the wind resistance design of the bridge is to prevent fatigue failure* and vibration caused by wind in various forms such as Vortex Induced Vibration, Buffeting, Flutter and so forth.

*Fatigue failure: The phenomenon where the material is destroyed after a certain period of time due to external forces that are repeatedly applied.

[Image of the large wind tunnel test for the sea bridge of the Sheikh Jaber Causeway in Kuwait. Hyundai E&C made a model that was about 1/150 in size to evaluate the safety of the bridge from various angles]

A vortex is a whirlpool that is generated when wind or current passes an onshore/offshore structure (obstacle). Vibration that is generated when the cycle of a whirlpool coincides with the vibration cycle of a building is called the vortex-induced vibration. Buffeting refers to the vibration of a building that is generated when an irregularly blowing wind strikes a building. Flutter is the cause of the collapse of the Tacoma Bridge, and this refers to the phenomenon where the vibration of a structure continues to rise even under a small load when the bridge enters an unstable state due to the interaction between the structure and the wind. Hyundai E&C creates the cross-sectional model of the top plate of the bridge based on the Law of Similarity* to evaluate the level of vibration in a small wind tunnel, and the result is reflected in design. Once the final draft of the design is finished, stability is tested again through a model that is approximately 1/150 of the entire bridge in a large wind tunnel.

*Law of Similarity: Law that allows one to interpret physical quantities relative to one another (an equation) when the scale of a phenomenon that actually occurs in nature and the scale of a phenomenon that is reproduced by an experiment are different.

[Cross-sectional 3D drawing of the top plate and the panoramic view of Ulsan Bridge. Ulsan Bridge, Korea’s longest and world’s third longest short span suspension bridge, is a project that shows a glimpse of Hyundai E&C’s technological capability of the wind tunnel design]

The most important part of the wind resistance design in a bridge is to determine the shape of the cross section. This is because the vibration level changes subtly depending on the installation of the median strip and the shape or the height of the bridge guardrail. Hyundai E&C selects the optimal shape of the cross-section after conducting a wind tunnel test by setting various variables such as the width and height of the cross-section of the tope plate, the location of the corner and the form of the attachment. For instance, Ulsan Bridge, Korea’s longest and the world’s third longest short span suspension bridge* was constructed on the coast where it is very windy. The side of the top plate was designed in a streamlined form that is similar to the cross-section of an airplane wing to minimize the uplift pressure* and the wind pressure while ensuring not to hinder the flow of the wind through the wind tunnel test. As for the Chacao Bridge in Chile that is being constructed as the multi-span suspension bridge, the initial design had the top plate with the width of 25m. Through experiments, 23.8m was identified to be the optimal width, and the completed design was one that secured both the economics and wind resistance performance. All long span bridge projects that Hyundai E&C participated in such as the sea bridge of Sheikh Jaber Causeway in Kuwait, Jobal Grand Bridge and Godeok Bridge (tentative name) applied the optimal wind resistance design that was obtained through a professional wind tunnel test.

*Short span suspension bridge: A suspension bridge that is connected with a single span which is the distance between towers.

*Uplift pressure: Pressure that pushes an object up from the bottom (the opposite force of gravity).

*Multi-span suspension bridge: A suspension bridge with three or more towers.

Secret to stable high-rise buildings?!

‘Buildings that are taller than 200m or with more than 50 floors’ are typically defined as high-rise buildings. Busan International Finance Center (289m), Bitexco Financial Tower in Vietnam (262m), Mok-dong Hyperion Towers (256m), and Lusail Plaza Tower (308m)’ that is emerging as the landmark of Lusail, Qatar, constructed by Hyundai E&C, all correspond to high-rise buildings. The archenemy of high-rising buildings is once again wind. Even under the same sky of Seoul, at a height of 100m, wind blows at the speed of 35 m/s and the speed is 52 m/s at a height of 600m. The impact is larger for taller buildings. According to the Korean Design Standard (KDS), if the height against the floor area (aspect ratio) is greater than 3 times, or in regions where the basic wind speed exceeds 34 m/s or on the coast (coastline of 3km), buildings must implement the wind resistance design by conducting a wind tunnel test. Hyundai E&C, the powerhouse in construction of housing and buildings carry out △ wind power test that measures the wind load*, △ wind pressure test that evaluates the wind load on the exterior such as windows or curtain walls, and △ wind environment evaluation that investigates the changes in the environment caused by the newly built buildings (Building wind*) and so forth to construct a building that is structurally safe. The measured data values are being used as the database for wind resistance design.

*Wind load: The force received on the perimeter of a structure when the wind blows.

*Building wind: Whirlpool of wind or gust of wind generated in between buildings when the wind splits after striking a building.

[Emerging landmark of Lusail, Qatar, ‘Lusail Plaza Tower’ being constructed by Hyundai E&C. Main tower consists of 5 underground floors and 70 ground floors, and it boasts to have the greatest number of ground floors in Lusail. Lusail Plaza Tower with its grand majesty also applied the wind resistance design]

Vibration acceleration (size of vibration) grows as the structure becomes taller. In the case of extreme acceleration in vibration, people in the building sometimes feel dizzy. Hyundai E&C that was the first to carry out the wind tunnel test on building structures in Korea has steadily conducted research to reduce vibration of buildings. Hyundai E&C is elevating the usability and the stability of the buildings by applying technology to absorb vibration energy such as AMD (Active Mass Damper) that minimize shaking by generating force in the opposite direction of vibration and TMD (Tuned Mass Damper) and TLD(Tuned Liquid Damper) that absorb vibration using liquid or mass body, such as the numbers of oscillations in a building, on wind resistance design.

[Image of the wind pressure test being carried out for the project on the new building of Amorepacific]

We sometimes get surprised by the strong wind that blows suddenly when we pass between buildings. This is the building wind that is often generated in large-scale housing complexes and high-rise buildings. In extreme cases, building wind would break the glass windows of high-rise buildings or damage the exterior. This is why it is called the ‘man-made disaster’. Building wind is generated when the fluid flow (air pressure) becomes stronger as the wind paths between buildings become narrower. Hyundai E&C identifies the causes of building wind in advance through the evaluation on the wind environment and conducts a thorough analysis of the impact of the air current on the surrounding environment when new buildings are being constructed. Hyundai E&C is implementing a human-centric design by changing the air current through the change in the landscape planting method for the comfort and safety of residents and pedestrians or through the installation of windshields and installing podiums* on the lower floors to prevent strong wind from the top floors of the building from coming down to the ground level.

*Podium: neighborhood facilities that are established in the lower floors at around first to third floors.

Skyscrapers and bridges that span widely without any limitations to the ground and the ocean show the limitless possibility of construction. Projects that stand tall after having overcome the wind and accumulating wind resistance research for close to 30 years prove that Hyundai E&C had the best wind resistance design capability in Korea. Experts on wind resistant structure at the R&D Center of Hyundai E&C also showed their pride and said, “The wind tunnel test of Hyundai E&C boasts of a high accuracy level with error range that is close to zero.” Wind resistance design is one that takes responsibility for safety above anything else. Wind resistance design transcended the calculation of wind to settle itself as the ultimate weapon of Hyundai E&C that overcomes wind.

*Wind resistant structure: structure that was safely designed so that the building does not collapse or exterior materials are not damaged due to wind. It is important that the building maintains its function even when it is under a strong wind.