Latest News

- Hyundai E&C Becomes Key Player in the Nuclear Decommissioning Market

- Hyundai E&C Accelerates Global Nuclear Expansion into the U.S. Nuclear Market

- Hyundai E&C Shifts into High Gear to Enter Nordic Large-Scale Nuclear Market

- Hyundai E&C Strengthens Korea-Japan Cooperation in Energy Transition and New Growth Businesses

- Hyundai E&C Signals Green Light for Large-Scale Nuclear Power Plant Business in Europe

[Focus on Energy] The History of Nuclear Power in Korea is the History of Hyundai E&C?!

South Korea and the United States have entered into a clean energy partnership, signaling a shift in the global energy market. The two countries have identified nuclear energy as a critical element in addressing the climate crisis and achieving carbon neutrality, and have expanded their relationship from a diplomatic and security focus to a “high-tech alliance” that includes nuclear power. The Korea-US alliance on nuclear power is also fueling Hyundai E&C's next-generation nuclear power plant business. Hyundai E&C will form “Team Holtec” with US energy company Holtec International to build 20 160-megawatt small modular reactors (SMRs) in Eastern Europe. It is also expected to accelerate the global expansion of the K-nuclear power plant(NPP) business by exploring global nuclear power projects with Holtec with the support of Korea's public financial institutions.

The nuclear renaissance is blooming again. Hyundai E&C has been the main contractor for 22 of the 34 largest Korean nuclear power plants at home and abroad, and was the first Korean construction company to build both pressurized light water reactors* and pressurized heavy water reactors*. Based on its impressive portfolio of building the largest number of NPPs in Korea and exporting the nation's first nuclear power plant overseas, the company is expanding its capabilities into next-generation nuclear power projects such as SMRs, nuclear decommissioning, and spent nuclear fuel storage facilities. Let us have a look at the history of Hyundai E&C's large-scale NPP projects since 1971 leading to its current status as a powerhouse in the nuclear power sector.

*Pressurized water reactor (PWR): A nuclear power reactor that uses low-enriched uranium (2-4%) as fuel and hard water (H₂O) as coolant. The primary and secondary systems are separated for high safety.

*Pressurized heavy water reactor (PHWR): A natural uranium-fueled nuclear power reactor that uses heavy water (D₂O) as a coolant. It is possible to change fuel during operation, but it requires a costly heavy water enrichment process. Wolseong Units 1 through 4 are pressurized heavy water reactors, while all other NPPs in Korea are pressurized light water reactors.

.jpg)

Dawn of the Nuclear Age(1970s)

Kori Units NPP 1 & 2 & Wolseong NPP Unit 1

.jpg)

In 1956, South Korea instituted a nuclear energy administration and promulgated the Atomic Energy Act in March 1958. As energy security and reliable supply of electricity became increasingly important, KEPCO, a former NPP operator, signed a contract in December 1970 to supply the Kori Unit 1 power plant with Westinghouse of the United States as the main contractor. This marked the beginning of the construction of Korea's first NPP.

Hyundai E&C's development history has followed a similar path with K-NPP. In the early days of NPP construction, the lack of domestic technology and experience forced Korea to rely entirely on foreign technology. The foreign main contractor was in charge of all aspects of the plant from construction to completion (on a turnkey basis). In the meantime, Hyundai E&C acquired technical skills by participating in the construction of the systems needed to operate the reactors. The 587-megawatt (MW) Kori 1 reactor first broke ground began commercial operation in April 1978, making Korea the 21st country in the world to own a nuclear power plant.

The construction capabilities and confidence gained from the construction of the Kori Unit 1 led to the award of the Kori Unit 2 project. The scope of Hyundai's participation in construction was also expanded, leading to the construction of the primary system*, which is the core process of nuclear power plant construction, and opening up the possibility of Korea's NPP technology independence.

*Nuclear power plants are divided into primary and secondary systems. The primary system is a reactor that produces steam using heat from nuclear fission, and the secondary system is a power generation facility that generates electricity by using steam to power turbines.

With construction beginning in May 1975 and completed in April 1983, Wolseong Unit 1 was the first "pressurized heavy water reactor" in South Korea, a completely different type from the "pressurized light water reactor" at the Kori NPP. The Korean government introduced Canadian pressurized heavy-water reactor design (CANDU) to diversify the supply route of source technology. Even Atomic Energy of Canada Limited (AECL), the owner of the original technology, had never constructed this type of reactor before, and the construction of Wolseong Unit 1 was fraught with many difficulties. In addition, the project had to be completed three to four months ahead of schedule in accordance with Korea’s national energy demand-supply plan. Hyundai E&C succeeded in shortening the construction time by four months, as promised, by constructing most of the primary system with stone pipes. Wolseong Unit 1 and Kori Unit 2 were completed in April and July 1983, respectively, allowing South Korea to have both heavy and light water reactor types around the same time.

Technology Accumulation Period (1980s)

Kori NPP Units 3 & 4 & Hanbit NPP Units 1 & 2

The 1980s marked the beginning of a new era for nuclear power in Korea. Nuclear power became an important part of Korea's electricity supply with the completion of one nuclear power plant after another. The state-led plan to localize nuclear power plant technology was in full swing, and Hyundai E&C's pace of technological advancement began to gain momentum. Hyundai E&C was selected as the main builder* and sole contractor for the Kori 3 and 4 projects. Korea Unit 3 was ranked No. 1 among 443 nuclear power plants in the world in the “2003 NPP Utilization Rate” published by <Nucleonics Week> magazine in the U.S. Unit 4 attained the "One Cycle Trouble Free (OCTF)" level five times, an indicator that demonstrates the stability and technical capability of NPP operations.

*Kori Units 3 and 4 were executed through a split order (EPCM+multiple prime contractors) method.

*One Cycle Trouble Free: It refers to continuous uninterrupted operation of a power plant after the first fuel load or after a fuel change until the next replacement of fuel.

The Hanbit NPP Units 1-6 (formerly known as the Yeonggwang NPP) in Yeonggwang-gun, Jeollanam-do, South Korea, were built by Hyundai E&C over 20 years and are responsible for 5% of South Korea's electricity production (as of 2021). Hanbit Units 1 and 2, like Kori Units 3 and 4, were constructed in a split order, each with a capacity of 950 megawatts. Hyundai E&C expanded the scope of applications of domestic technology to the electrical and mechanical fields in addition to civil and construction processes with Hanbit 1 and 2.

Technology Self-Reliance Period (1990s to early 2000s)

Hanbit NPP Units 3-6 & Wolseong NPP Unit 2

.jpg)

Hanbit Units 3 and 4 were built entirely by Korean engineers. To lay the foundation for nuclear technology self-reliance, KEPCO changed the system to select domestic companies as the main contractors for each domain, with foreign companies participating as subcontractors to the domestic main contractors. In November 1987, Hyundai E&C was selected as the sole contractor for Hanbit Units 3 and 4 through a selective tendering. This was the moment when Hyundai E&C's relentless efforts to establish technical cooperation with leading international companies and launch a dedicated team to obtain ASME (American Society of Mechanical Engineers) certification, a requirement for overseas nuclear projects, began to shine

The design and construction of Hanbit Units 3 and 4 began in December 1989, and in December 1991, the final stage of reactor and installation, began. Instead of the conventional method of installing the reactors through a temporary exit adjacent to the ground, Hyundai E&C was the first to try and succeed in a new construction method that involved lifting the reactors onto a platform 14 meters above the ground and placing them into the containment building through a machine entrance. Hanbit Units 3 and 4 were the first Korean-led projects to receive support from foreign companies only in areas where the technology was not yet mature, and this served as the driving force behind the creation of the first Korean Standard Nuclear Reactor (KSNR), Hanul Units 3 and 4.

The construction of Hanbit Units 5 and 6 focused on improving the issues identified during the construction and operation of KSNR Unit 1. Hyundai E&C built an advanced nuclear power plant based on its accumulated technology and experience. Despite unforeseen challenges such as the Asian financial crisis, it not only met the contractual deadlines, but also upgraded the performance of the KSNR to a higher level by increasing both the economic efficiency and safety of the plant.

Meanwhile, Wolseong Unit 2 began construction in October 1991, 16 years after Unit 1. Hyundai E&C perfected quality by developing new construction methods such as Slipform* and PS (Pre-Stressing). With the completion of Wolseong Units 1 and 2, Hyundai E&C became the first Korean builder to accumulate construction technology in both light and heavy water reactors. The company solidified its position as a leader in NPP construction with the most advanced technology and track record.

*Slipform: A method of constructing a concrete structure for the outer wall of a nuclear reactor in a short period of time by making a formwork of a certain shape in which concrete can be poured continuously and moving the formwork upward little by little using a jacking system.

Technology Advancement Period (2000s)

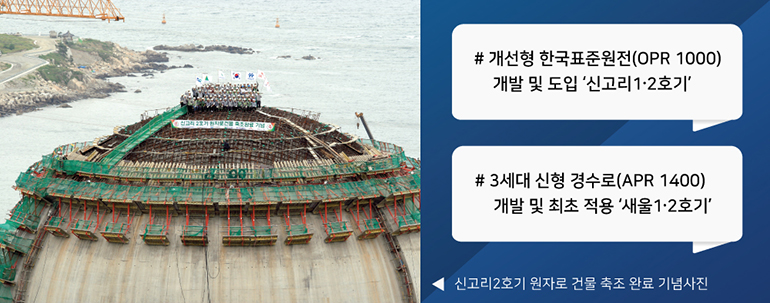

Shin Kori NPP Units 1 & 2 & Saeul NPP Units 1 & 2

The 2000s marked a turning point in the history of nuclear power in Korea. The KEPCO's power generation division was split into six companies, the main operator of the nuclear power business being Korea Hydro & Nuclear Power Co. The KSNR further evolved through steady localization of nuclear power technology. Shin Kori Shin-Kori Units 1 and 2 were the first nuclear power plants to introduce the OPR 1000 (Optimized Power Reactor 1000 MW), an "improved Korean standard NPP". OPR 1000 is a new name for the KSNR targeted for overseas expansion, and it reflects the improvements made to the KSNR and is referred to as Korea's second-generation nuclear power plant.

At Shin-Kori Units 1 and 2, domestically produced nuclear equipment such as an integrated reactor superstructure and a power plant monitoring and alarm system were introduced. Emergency cooling water injection pipes and passive hydrogen removal system were adopted to greatly enhance the safety of the reactors. In order to prevent changes in the marine environment due to NPP construction, Hyundai E&C also introduced the first underwater tunnel in Korea to collect and drain cooling water. In particular, the company was the first to apply new construction methods such as composite structure construction and automatic welding of reactor coolant pipes, which helped improve the economics and technology of NPP construction.

Saeul Units 1 and 2 (formerly known as Shin Kori Units 3 and 4*) are the first third-generation nuclear power plants to utilize the Advanced Power Reactor 1400 (APR 1400 MW), a new generation of light water reactors. They are earthquake-resistant to withstand a magnitude 7.0 earthquake and extremely safe, boasting only a 1/1 million chance of a meltdown*. The design life has also been significantly increased to 60 years from 40 years. Saeul Units 1 and 2 first broke ground for construction in September 2007, more than two years ahead of the order for the Barakah NPP in the UAE, which marked Korea's first NPP export. The project was of great significance to both Korea and Hyundai E&C as it demonstrated the superior performance of the APR 1400.

*In November of last year, the name of Saeul NPP Division was changed to Saul Unit 1-4, to be consistent with Shin-Kori Unit 3-6.

*Meltdown: A serious nuclear accident in which the core of a reactor melts down.

Technology Independence/Overseas Export Period (2010s)

Shin-Hanul NPP Units 1 & 2 & Barakah NPP, UAE

.jpg)

Shin Hanul Units 1 and 2, located in Uljin-gun, Gyeongsangbuk-do, are the second APR 1400 NPPs in Korea. Shin Hanul 1, which began construction in April 2010 and was completed in December 2022, is the first power plant in Korea to achieve “100 percent localization of construction technology and 100 percent localization of design and equipment" by localizing the Man-Machine Interface System (MMIS), Reactor Coolant Pump (RCP), and core design code, all of which were previously non self-reliant technologies. In particular, the MMIS, which serves as the “brain of a NPP”, is a system that integrally manages NPP operation, control, monitoring, and measurement, and is evaluated as superior in terms of stability and convenience compared to MMIS of foreign companies.

Construction of Shin Hanul Units 1 and 2 is a project that will serve as the benchmark for the construction of APR 1400 models at home and abroad in the future. Shin Hanul Units 1 and 2 are equipped with double and triple safety measures to prepare for all possible nuclear events. 41 design changes were made to enhance overall safety. Shin Hanul 1, which began commercial operation on December 7, 2022, is responsible for 1.18% of Korea's annual electricity production (based on a 90% operating rate in 2021). Next to Shin Hanul Unit 1, the identical Unit 2 is being prepared for operation, and Hyundai E&C is working tirelessly to complete Shin Hanul Unit 2 by the end of the year.

The 2010s also marked the company's first nuclear export. The company won a mega project to build four 1,400-megawatt NPPs in Barakah, west of the UAE capital Abu Dhabi. In December 2009, a consortium consisting of Hyundai E&C, KEPCO, and Korea Hydro & Nuclear Power was selected to build the $20 billion mega-nuclear power plant, beating off stiff competition from France, the United States, and Japan. The Barakah NPP in the UAE, which is being built by Team Korea, is 8 kilometers across and 1.8 kilometers long, making it four times the size of Yeouido. The upper dome of the reactor building, inspired by an Islamic mosque, goes up to 80 meters, similar to the height of a 30-story apartment building. The Barakah NPP, which broke ground in July 2012, currently has Units 1 and 2 in commercial operation, and Unit 3 has finished preparations for operation with fuel loaded. Hyundai E&C is also working hard to kick start Unit 4 by the end of next year. When fully operational, these four units will supply up to 25% of the UAE's electricity needs.

Hyundai E&C has begun a race to globalize “K-NPP” by exporting NPPs to the UAE. In addition, in May last year, the company signed a strategic cooperation agreement with Westinghouse, becoming the first Korean company to enter the global market for the AP 1000 project. By jointly participating in the AP 1000 project, which is licensed in the U.S., Europe, and Asia, the scope of Hyundai E&C's large NPP business is expected to be further expanded. Hyundai E&C plans to lay the foundation for a sustainable future business and accelerate its competitiveness through Korea-US cooperation on nuclear power business.

Next-generation nuclear period (2020s)

Planned construction of small modular reactors (SMRs) in U.S. and Eastern Europe

Hyundai E&C is expanding its business into all areas of nuclear power generation based on its competitive advantage in large-scale Korean NPPs. Hyundai E&C is thriving as a "Total Solution Creator" with expertise not only in NPP construction but also its maintenance, performance improvement, and technical consulting services, as well as nuclear decommissioning and construction of spent fuel storage facilities.

In particular, the company stands out in the next-generation NPP business. In November 2021, Hyundai E&C signed a teaming agreement with an American nuclear power company Holtec International to develop SMRs and enter the business together, and in March of the following year, it signed a business agreement to enter the NPP decommissioning business, gaining traction in the next-generation NPP business. The results are also impressive. Hyundai E&C is developing SMR-160 (Small Modular Reactor 160 MW), a general-purpose reactor that can be deployed without regional and environmental constraints, including deserts and polar regions, with its nuclear power plant partner Holtec. The SMR-160 will first be deployed at the Holtec-owned Oyster Creek Nuclear Decommissioning Site in the U.S., and will also be built in Ukraine to help rebuild the country's energy infrastructure. Team Holtec also plans to connect the SMR-160 pilot project to the grid in Ukraine by March 2029 and deploy additional 20 units. To this end, Hyundai E&C will develop an efficient implementation plan and make efforts to locally produce the components required for the construction of the reactor.

In addition, the technical cooperation between Hyundai E&C and Holtec will be supported by public financial institutions such as the Korea Trade Insurance Corporation and the Korea Export-Import Bank of Korea, further strengthening Hyundai E&C’s position in the global nuclear power market. Taking this as a stepping stone, Hyundai E&C is committed to securing source technologies and capabilities for next-generation nuclear power projects including SMRs and nuclear decommissioning.

[ MOU signing ceremony for SMR support between Hyundai E&C, Holtec, and Korea Trade Insurance Corporation during the Korea-U.S. Summit ]

After 50 years of writing nuclear power history in Korea, Hyundai E&C is now dreaming even bigger. It aspires to become a game changer in the global nuclear power industry by leading the development of the nuclear ecosystem, from design and construction of next-generation NPPs to nuclear decommissioning. The nuclear energy history that Hyundai E&C will continue to write as a top global builder beyond Korea has already begun.