Latest News

- Hyundai E&C Employees Spread Holiday Warmth to Underserved Neighbors in the Community

- Hyundai E&C Launches ‘Winter Site Safety Inspection Relay Campaign’

- Hyundai E&C Becomes First to Surpass KRW 10 Trillion in Urban Redevelopment Orders

- Hyundai E&C Recognized as a ‘Company that Contributes to the Local Community’ with Highest Grade for 3 Consecutive Years

- Hyundai E&C Publishes Brand Book Commemorating 10th Anniversary of ‘THE H’

Charting Singapore`s New Coastline on Open Water

.png)

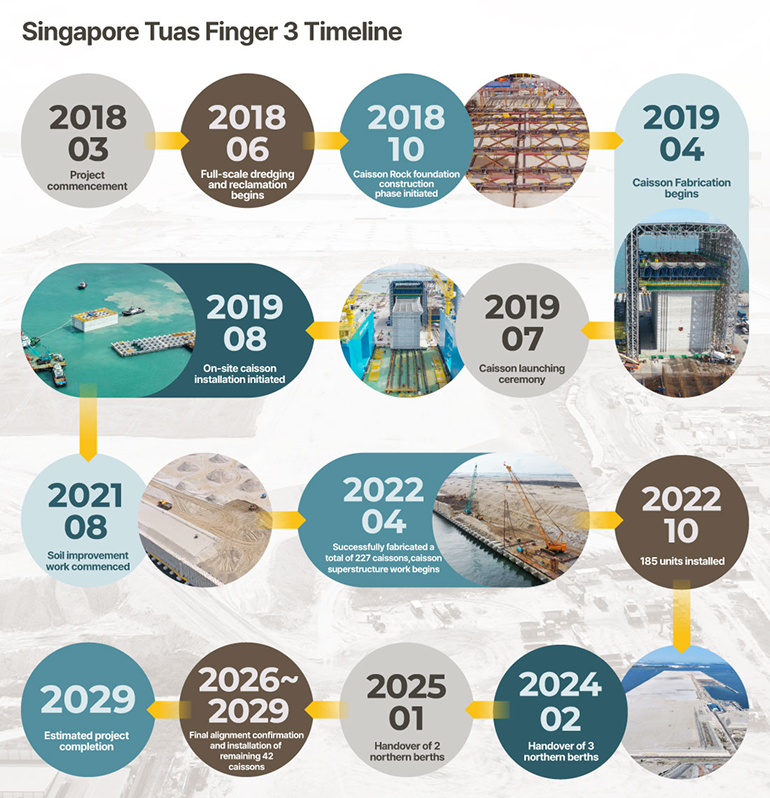

Anchoring massive caissons—each as tall as a 12-story apartment building—firmly in place amid constantly shifting seabeds and tidal currents in the middle of the ocean is no simple feat. The Tuas Finger 3 Project, which is transforming Singapore's waters into a functioning port, represents a round-the-clock sequence of highly demanding operations, from precision caisson fabrication through transportation to installation. Having successfully completed Tuas Finger 1 in 2021 and demonstrated its offshore technical capabilities and operational expertise, Hyundai E&C is now leveraging automation technology and skilled personnel to guide this new project steadily toward successful completion. Join us as we explore the construction site of Tuas Finger 3, where a new coastline is taking shape.

.png)

The Heart of Tuas Mega Port: Finger 3

Singapore has leveraged its position as a maritime crossroads linking Asia, Europe, and the Middle East to emerge as one of the world's premier logistics hubs. To accommodate growing vessel traffic and container volumes, Singapore is constructing Tuas Mega Port—a massive offshore platform consolidating multiple terminals into a single integrated facility. This mega-project, initiated in 2011, is planned for phased completion over a 40-year period extending through 2050.

![Tuas Finger 3 by the Numbers Tuas Finger 3 by the Numbers [Caissons] 227 units – Total number of caissons 9.1 km – Total length when connected (equivalent to a round trip from Yeouido to Gwanghwamun in a straight line) 25m × 43m × 30m – Dimensions of each caisson (height of a 12-story apartment building) 13,500t – Weight per unit [Hyundai E&C Technical Capabilities] Maximum 83 hours – Casting time per unit Maximum 9 units – Caissons that can be fabricated per month 2020 – WSH Awards 2020 Gold Medal / Hyundai E&C Awarded the Grand Prize for Innovation 20,000t – Weight of the floating dock custom-built by Hyundai E&C](/FileContents/EditorImg/20260107/4.png)

Tuas Finger 3 constitutes a core section of Tuas Mega Port. At approximately 1.3 times the area of Seoul’s Yeouido Island, the installation of 227 caissons makes this the largest single project of its kind in Singapore's history. A caisson is a large hollow concrete box structure installed on the seabed to form the foundation for offshore infrastructure such as breakwaters, quay walls, and bridge footings. The caissons built here reach approximately 30 meters in height—equivalent to a 12-story apartment building—and weigh up to 13,500 tons each. If all 227 units were connected end-to-end, they would stretch the distance of a round-trip journey from Yeouido to Gwanghwamun in a straight line.

Hyundai E&C has already established a proven construction framework through the successful manufacturing and installation of 198 caissons during the Tuas Finger 1 project, completed in 2021. Leveraging this experience on Finger 3—where construction methods and process configurations are largely similar—the company has mobilized initial equipment and personnel while rapidly achieving production line stabilization. Hyundai E&C overseas the entire construction process from caisson fabrication through installation, playing a pivotal role in the development of Tuas Mega Port.

Building Foundations at Sea: 227 Caissons

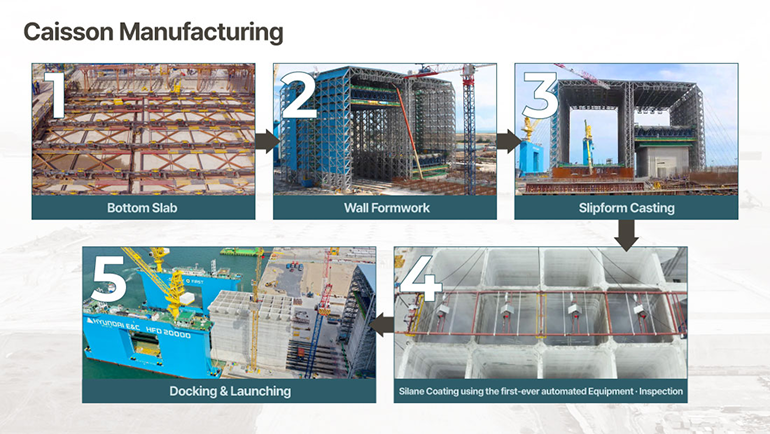

#1 Caisson Manufacturing

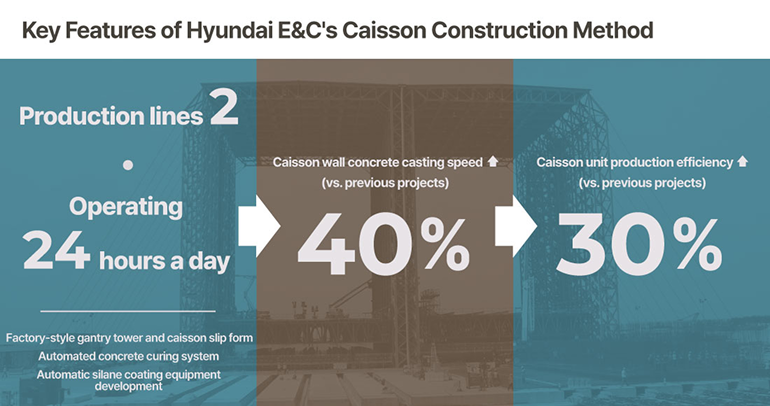

The essence of caisson manufacturing lies in precisely stacking massive concrete structures to heights of several dozen meters. The Tuas Finger 3 Project employs a factory-style gantry tower and automated slip form method, continuously lifting formwork while casting concrete. This approach enables real-time adjustment of lifting speed, angle, and equipment loads to maintain uniform joint quality while flexibly adapting to changing external environmental conditions. Similar to an automotive production line with conveyor belts, structures can be fabricated and moved simultaneously, minimizing worker intervention and enhancing overall process efficiency and safety. Two production lines operated continuously 24 hours a day on-site. To maximize productivity while maintaining high quality, both lines had to move at precisely the same speed, with all operations—casting, curing, rebar placement, and repairs—following an exact cycle. Site personnel unanimously agree that establishing the optimal cycle through extensive trial and error represented the most challenging aspect of the production operation.

To maintain consistent quality, Hyundai E&C leveraged a diverse array of automation technologies. An automated concrete curing control system precisely manages curing temperatures, while high-performance pump technology increased concrete transfer speed by 60%, reducing wall casting time by 40%. The caisson superstructure incorporates Hyundai E&C's exclusive patented technology— Automated Silane Coating Equipment Development. While silane coating is essential for preventing seawater penetration into concrete surfaces, traditional methods required workers to perform manual application atop the caisson, posing significant safety risks. The introduction of automated equipment enabled silane application and repairs through simple ground-level button controls, simultaneously bolstering work safety and uniform quality. This technology received recognition with a Singapore Workplace Safety & Health Innovation Award Gold Medal in 2020 and a Hyundai E&C Innovation Award, validating its excellence.

Thanks to these technological innovations, Hyundai E&C successfully manufactured up to 9 caissons per month, demonstrating 30% higher productivity compared to previous projects.

From Floating Dock to Sea and Subsequently to Land

#2 Caisson Installation

Fabricated caissons are transferred from land to sea using Hyundai E&C's custom-built 20,000-ton floating dock (HFC 20000). This equipment was designed to support caisson installation work from Finger 1 through Finger 3. By filling or draining internal tanks to adjust buoyancy, the caissons are first lifted horizontally before being towed by tugboats to their installation points. A dedicated barge then precisely positions each caisson. During this phase, GPS, depth, and tidal current data are simultaneously monitored for fine adjustments down to the centimeter. Once the seabed foundation and structure settle into place, the outline of a new coastline begins to emerge.

Hyundai E&C operates more than 20 units of large-scale offshore equipment, including the Frontier vessel for offshore wind projects, enabling successful completion of all processes from caisson fabrication through transport and installation.

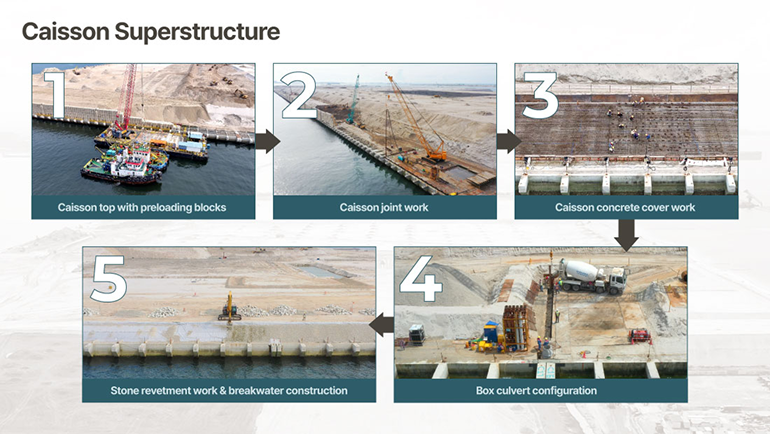

#3 Caisson Superstructure Construction

Once these "walls at sea" are erected, work immediately begins on establishing the "land foundation". This stage is essential for structures to remain stable over extended periods in harsh environments. First, preloading blocks are placed atop caissons to add sufficient weight in advance and secure the caissons in place; once stabilization is complete, the preloading blocks are removed.

Joints (connections) between caissons must also be reinforced. As sections that determine structural watertightness and durability, gaps are filled with geotextile and aggregate, then concrete is cast to seal even microscopic spaces and block seawater intrusion. Subsequently, concrete covers are installed atop caissons to prevent internal settlement and block soil infiltration.

In large-scale reclamation ports, drainage systems equate to improved stability. At the Tuas Finger 3 site, box culverts (drainage channels) are installed to create pathways for natural rainwater and seawater flow, while layered stone revetments are stacked on the perimeter to protect reclaimed land from waves, currents, and erosion. Upon completion of superstructure work, caissons serve as sites for container terminals and quay walls.

A New Coastline That Will Anchor Global Maritime Infrastructure

The site has currently surpassed an 82% progress and is entering its final phase. With a quarter of the 20 berths completed, installation of the remaining 42 caissons and a variety of infrastructure work is accelerating toward the 2029 completion target. Through this project, Hyundai E&C has overseen the entire caisson construction process, demonstrating its technical capabilities and construction expertise in the global market. Notably, in the labor-intensive caisson manufacturing sector, the company managed the safety of nearly 1,000 workers from overseas and recorded zero accidents even amidst the pandemic.

The Tuas Finger 3 Project extends beyond simple port construction to drive innovation in Singapore's maritime industry. Upon completion, it will serve as a new hub for Asian maritime traffic, playing a central role in reshaping the global logistics network. Following this new map drawn upon the ocean, Hyundai E&C continues today to precisely position each successive caisson, completing the contours of tomorrow's port.

"This is a site where the sea changes daily. Each time a caisson settles into place, the reality that we're creating a new city's coastline feels tangible. We will complete the remaining work without wavering until the very end."

—Kim Dae-woong (Team Lead), Project Execution Team, Hyundai E&C Singapore Tuas Finger 3 Reclamation Project

[On April 25, 2022, a ceremony commemorating the completion of all 227 caissons was held on site]

[YOUTUBE] Singapore Tuas Finger 3 Project