Latest News

- Hyundai E&C Employees Spread Holiday Warmth to Underserved Neighbors in the Community

- Hyundai E&C Launches ‘Winter Site Safety Inspection Relay Campaign’

- Hyundai E&C Becomes First to Surpass KRW 10 Trillion in Urban Redevelopment Orders

- Hyundai E&C Recognized as a ‘Company that Contributes to the Local Community’ with Highest Grade for 3 Consecutive Years

- Hyundai E&C Publishes Brand Book Commemorating 10th Anniversary of ‘THE H’

Korea`s Largest, Uninterrupted Heartbeat of Data: Pacific Sunny Data Center

.png)

Data centers possess unique characteristics that distinguish them from conventional buildings—they must operate without interruption. With servers and other equipment running 24 hours a day, stable power supply and efficient cooling systems are essential. The Pacific Sunny Data Center in Jukjeon, Yongin, Korea's largest facility of its kind, has realized the core data center values of "uninterrupted power and continuous operation" through Hyundai E&C's differentiated construction technologies.

Korea's Largest Data Center, Born Through 43 Months of Dedication

The Pacific Sunny Data Center in Jukjeon, Yongin, Gyeonggi Province, is revealing its commanding presence ahead of completion at the end of September. With a total floor area of approximately 100,000 m², an IT load of 64 MW, and a power receiving capacity of 100 MW, this facility can supply enough electricity for approximately 160,000 to 200,000 households* to operate simultaneously all day long, making it one of Korea's premier hyperscale data centers.

Hyundai E&C, which boasts Korea's most extensive data center construction portfolio including the NH Integrated IT Center and Naver’s GAK Sejong Data Center, has demonstrated its technical capabilities and expertise once again with the Pacific Sunny Data Center. Data centers, in particular, require stable power supply, demanding the highest levels of stability and attention to detail at construction sites. Hyundai E&C has constructed ultra-large-scale power facilities and cooling systems with precision while also taking into account noise and safety issues in neighboring communities. Despite these demanding conditions, the site faithfully exceeded global standards—including a Power Usage Effectiveness (PUE) rating of 1.3 (an energy efficiency metric), compliance with international TIER 3 certification (an international reliability standard), and carrier-neutral architecture—while maintaining construction progress without setbacks.

*Calculated based on average household power consumption of 0.5~0.6 kW

Spatial Configuration Encompassing Stability and Scalability

The Pacific Sunny Data Center project in Jukjeon, Yongin broke ground in February 2022. The site progressed through major construction phases sequentially—earthwork, steel frame construction, and structural work. Starting in 2023, structural work and interior/exterior finishing proceeded simultaneously as the building began to take on its full form.

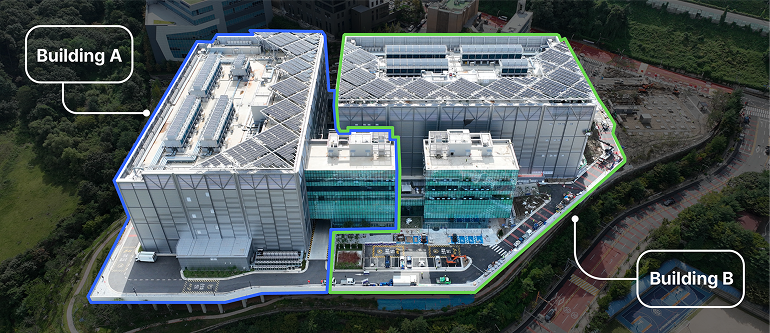

As 2024 arrived, the site became increasingly sophisticated. Countless electrical, mechanical, and telecommunications systems filled every corner, with piping and cables connecting the entire building like massive blood vessels. As a result, construction was completed on Building A in December 2024, while Building B is also approaching completion at the end of September 2025.

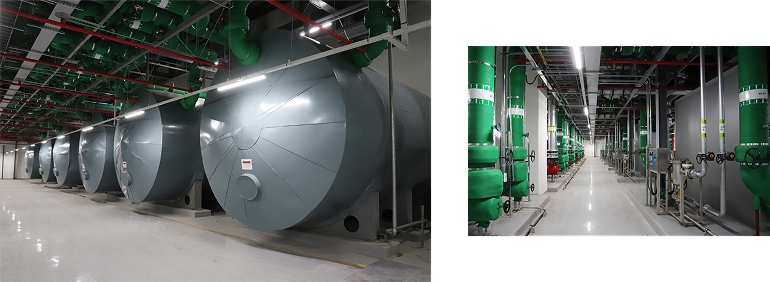

The interior spaces in their final stages are particularly noteworthy. The third basement level houses chillers, cooling towers, and pumps to cool heat generated by servers, serving as the literal heart of the data center. This floor incorporates redundant design principles to guarantee uninterrupted data center operations under any and all circumstances.

The second basement level contains emergency generators, fuel tanks, and Uninterruptible Power Supply (UPS) systems, enabling continuous operation even when external power is cut off. The first basement level serves as parking and space for operational personnel and visitors, while floors 1 through 4 above ground are densely packed with thousands of server racks. The Pacific Sunny Data Center thus functions as a specialized structure where ultra-high-speed networks, precise temperature and humidity control, and advanced fire suppression systems organically combine to enable consistently stable data processing.

[Third basement level mechanical room panorama. This floor features large buffer storage tanks holding chilled water used to cool servers (left), a wide array of instrumentation equipment (valves, flow meters, etc.) for chilled water/cooling water circulation and temperature/pressure control]

PUE 1.3 and TIER 3: Validating Global Standards

The Pacific Sunny Data Center represents a comprehensive embodiment of global standards, deploying advanced technologies and construction methods befitting its status as Korea's largest facility. To maximize energy efficiency, high-efficiency cooling systems, state-of-the-art UPS units, and power distribution networks minimizing losses were installed without any gaps in coverage. This setup achieved a PUE of 1.3, an industry-leading metric. Additionally, 154 kV high-voltage power is directly received from substations through underground lines to the data center, ensuring a maximum power receiving capacity of 100 MW. This established a degree of energy supply reliability comparable to global cloud enterprises and created an uninterrupted operational foundation insulated from external shocks.

[Data hall with racks arranged in rows where IT equipment including servers will be installed in large numbers (left), substation facilities ensuring stable supplies of 154 kV ultra-high voltage power (right)]

Securing a high degree of stability necessitated even more meticulous attention to detail. To meet international TIER 3 standards, all core infrastructure—electrical, mechanical, and cooling—was designed with dual and triple redundancy. The impressive performance realized here transcends mere "numbers". It represents outcomes that simultaneously embody both energy efficiency and operational stability, providing evidence of delivering internationally recognized, globally standardized, and reliable infrastructure.

The Strength to Endure: Secrets of Data Center Structure

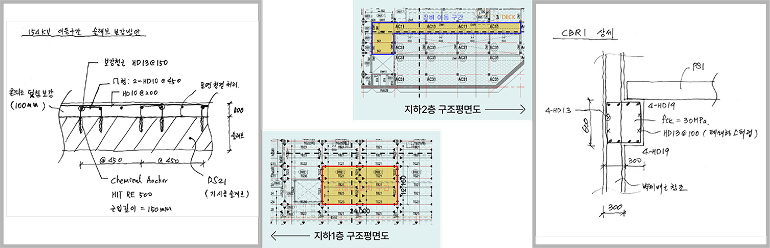

Data center floors and building structures are distinctly different from conventional buildings. They must withstand tremendous loads and vibrations while also guaranteeing continuous energy supply. Numerous servers and large-scale electrical equipment are essential, and these systems are inherently high-load. Therefore, unlike typical office buildings, the Pacific Sunny Data Center features thick slabs and dense reinforcement structures capable of withstanding loads up to 2 tons per square meter, sturdily supporting this added weight. Additionally, a raised access floor design was introduced to precisely control vibrations generated during equipment operation, and temporary supports and dedicated slabs were used for heavy equipment delivery, establishing a "data center-worthy foundation" from the initial stages.

[Drawings for 300-ton crane installation and equipment movement (center) and sketches of permanent support structures (TSC beams) used to mitigate heavy equipment loads and provide floor reinforcement]

In addition, Hyundai E&C utilized post-tension structural technology to withstand ultra-heavy equipment loads. This method, which inserts steel tendons inside concrete and then tightens them to create compressive force, firmly secures structures so they don't shake even when heavy equipment—large server racks, generators, and cooling equipment—operates simultaneously. As a result of this ingenuity, the core of the data center serves as a solid foundation of structural support without sacrificing stability.

[(From left) Process of inspecting steel strand materials for post-tension construction, installing steel strands in the structure (middle), tensioning work to apply force by tightening steel strands]

Precision Construction and Repeated Testing: The Source of Perfectly Uninterrupted Power

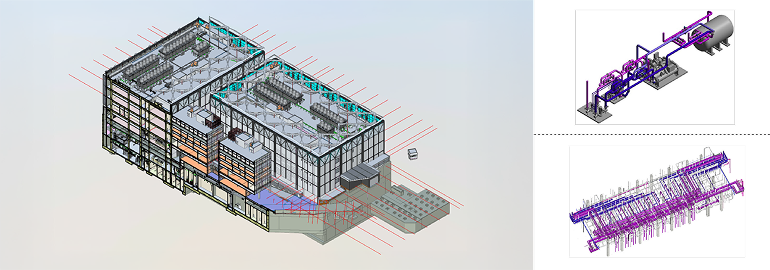

The site represented a continuous sequence of inconspicuous precision-oriented processes and thorough verification. In an environment where hundreds of kilometers of piping and cables and countless systems were intricately intertwined, Hyundai E&C conducted multiple Building Information Modeling (BIM) simulations to ensure all equipment and piping was installed correctly without giving rise to any interference.

[Architectural/structural BIM (left), mechanical room equipment system diagram (upper right), mechanical room piping and supports (lower right)]

Throughout the entire design and construction process, specialized quality control personnel from each line of work conducted site inspections, systematically performing precision construction and inspections according to process-specific checklists. In concrete casting, piping, and electrical processes, even minute discrepancies were corrected to enhance construction quality. Additionally, real-time quality monitoring systems were put in place, and regular workshops and quality training sessions were conducted with partner companies to mitigate even minor mistakes and risks in advance.

However, the truly critical moment unfolded after all equipment installation was completed. After confirming individual equipment performance through function tests, integrated function testing put major systems—power, cooling, and networks—through their paces simultaneously under conditions identical to actual operations. When servers emitted hot air, cooling systems immediately responded, and meticulous verification confirmed whether UPS units supplied power without the slightest fluctuation.

Behind these results lay "real-world operational safety mechanisms" that designed all core infrastructure—UPS units, emergency generators, and power distribution panels—with dual and triple redundancy so that when one set of equipment stopped working, another line immediately assumes its role. Moreover, during commissioning, rigorous tests were conducted that intentionally shut down certain lines, creating an operational system that guarantees continuous data flow under any fault condition.

Collective Efforts Overcomes Crises and Sets New Standards

During the 43-month journey, the site contended with various variables and challenges. Critically, the new construction site contained far more buried waste than anticipated, requiring considerable time to conduct demolition, waste sorting and disposal concurrently. Compounded by commercial challenges stemming from civil complaints including opposition to data center construction and noise issues during exam periods at a nearby high school, meeting the original completion deadline of August 30, 2024, became virtually impossible.

A breakthrough emerged from what all considered a formidable challenge. On August 22, 2024, a global Cloud Service Provider (CSP) finalized its decision to occupy five additional floors, resulting in a contract amendment including a 15-month schedule extension and a construction cost increase of KRW 321.5 billion (excluding VAT), allowing the project to reach a new turning point. However, even after securing this new breakthrough, another major challenge awaited. The global tenant's stringent requirements exceeding domestic standards and demanding commissioning tests had to be satisfied. In spite of all this, the site successfully achieved partial completion of Building A on December 30, 2024, dispelling concerns among lenders and various stakeholders and marking an important milestone proving the project's credibility and execution capability.

Amidst these unpredictable variables and challenges, all site employees communicated closely with partners and the client to solve problems. Despite the sudden increase in scope and the unique demands of the global CSP, every department and partner worked as one to rapidly reflect design changes and minimize delays. This experience served as an opportunity to deeply reaffirm the value of collaboration and teamwork.

Now, the site is on the verge of fruition. Ha Tae-ho, Site Manager of the Pacific Sunny Data Center, expressed his thoughts on the upcoming completion, "The Pacific Sunny Data Center is the culmination of the technical experience and operational know-how Hyundai E&C has accumulated through constructing numerous data centers. I hope this project becomes a significant milestone that further illuminates Hyundai E&C’s name in future data center projects and the broader digital infrastructure market."