Latest News

- Hyundai E&C Employees Spread Holiday Warmth to Underserved Neighbors in the Community

- Hyundai E&C Launches ‘Winter Site Safety Inspection Relay Campaign’

- Hyundai E&C Becomes First to Surpass KRW 10 Trillion in Urban Redevelopment Orders

- Hyundai E&C Recognized as a ‘Company that Contributes to the Local Community’ with Highest Grade for 3 Consecutive Years

- Hyundai E&C Publishes Brand Book Commemorating 10th Anniversary of ‘THE H’

Building the Future with Water: Hyundai E&C’s Global Water Projects

Water is more than a mere resource for survival; it is the core infrastructure that determines the future of industries, cities, and nations. Sprouting the seeds of industry on the arid soil of the desert, breathing new value into discarded water, and creating sustainable energy from the immense power of nature—wherever water is needed, Hyundai E&C is creating change.

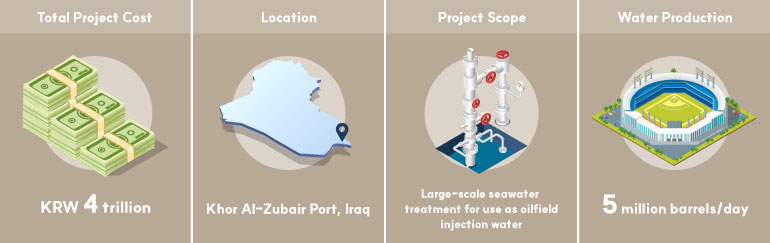

Iraq Water Infrastructure Project

Awakening the Heart of the Oilfield with Seawater

The Basra region of southern Iraq is home to one of the world's largest oil reserves. Here, 'water' is synonymous with 'oil.' As part of efforts to increase crude oil production, water must be injected into the underground reservoirs to raise the oil pressure. Existing freshwater sources like wells and rivers are insufficient to handle the vast demand for 'industrial water.' Yet, in the arid desert, every drop of water is precious. For Iraq, which relies on crude oil exports for over 90% of its national income, water scarcity was a critical problem, directly leading to a decline in oil productivity.

Hyundai E&C has emerged as the solution provider for this industrial water shortage in southern Iraq's oilfields. This past September, the company secured the mega-scale Water Infrastructure Project (WIP), part of a comprehensive Gas Development Integrated Project that encompasses oil, solar, and seawater treatment within Iraq. This plant, to be constructed near the Khor Al-Zubair Port approximately 500 kilometers southeast of the capital, Baghdad, is a massive facility with the capacity to produce 5 million barrels of water per day, with a total project scale exceeding KRW 4 trillion. It is a multi-process package combining intake, pre-treatment, transmission with long-distance pipelines, and power substations and other facilities. The water produced here will be used to enhance crude oil production at Iraq's flagship oilfields in the southern Basra region, such as West Qurna and South Rumaila.

The daily seawater processing capacity is an astonishing 5 million barrels (1 barrel = approx. 159L, or about 795,000 m³). This is equivalent to filling approximately 318 Olympic-sized swimming pools* or filling Seoul’s Jamsil Baseball Stadium* 6.2 times. Here, seawater is not merely purified; it is transformed into the 'lifeblood of industry,' maximizing oilfield productivity.

*Olympic-sized swimming pool: 50m×25m×2m = 2,500 m³

*Jamsil Baseball Stadium volume: Field area (122m×106m) × Height 10m = 129,320 m³

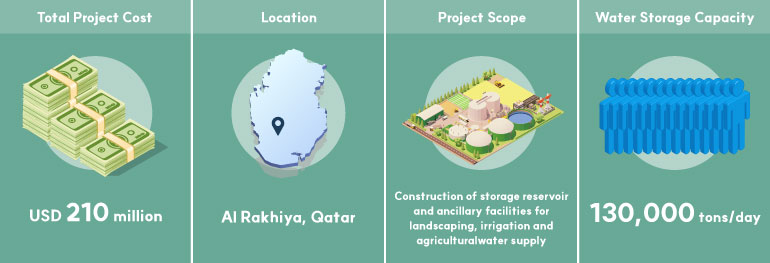

Qatar TSE Storage Facility Project

‘Discarded Water’ Transformed into Qatar's Survival Strategy

With an average annual rainfall of only 75mm, Qatar is one of the world's most water-stressed nations. Rapid urbanization, population growth, and the hosting of large-scale international events such as the 2022 FIFA World Cup led to an explosion in water demand, while resources remained critically scarce. To address this water shortage, Qatar designated the use of Treated Sewage Effluent (TSE), water that has undergone proper treatment at wastewater plants, as a national priority. However, TSE recycling systems require a high degree of technical sophistication, and the lack of storage infrastructure led to a vicious cycle where this precious water resource was simply being discarded.

Hyundai E&C has provided a sustainable solution to Qatar's water scarcity problem. The recently completed Qatar TSE Storage Facility is the answer. This project is a key piece of infrastructure that stores large volumes of highly purified TSE to ensure a stable supply of water to the agricultural, landscaping, and industrial sectors. The mega-scale TSE storage reservoir, constructed in Al Rakhiya, about 50 kilometers southwest of the capital, Doha, is a colossal water ‘warehouse’ with a capacity of 22.5 million m³. It can store over 130,000 tons of recycled water per day, an amount equivalent to the daily water consumption of approximately 7% of Qatar's entire population.*

Hyundai E&C made use of specialized materials with outstanding corrosion resistance to withstand the extreme climatic conditions and high-salinity environment in Qatar, while also ensuring stable water quality during long-term storage through a real-time water quality monitoring system. What was once discarded wastewater is now being reborn as a 'new water of life,' greening Qatar's landscapes and invigorating its industries. This massive water reservoir, built in the middle of the desert with Hyundai E&C's technological prowess, is more than just a storage facility; it has become a symbol of the circular economy that Qatar aspires to create.

*Calculated based estimates of a population of approximately 3 million people in Qatar and a per capita water consumption of 590L/day.

[Source: World Health Organization (WHO) 2023, Government of Qatar 2025]

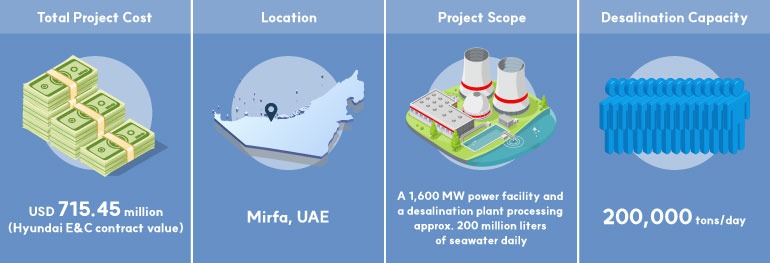

UAE Mirfa Independent Water and Power Plant

Abu Dhabi’s ‘Water Hub,’ Built in the Middle of the Desert

The UAE is also one of the most severely water-stressed nations globally. On this arid land, where only a minuscule amount of rain (30~40㎜) falls once or twice a year, the demand for power and water has snowballed due to rapid urbanization and population growth. While its crude oil and natural gas reserves rank 3rd and 4th in the world, the drinking water and domestic water resources essential for the survival of its people were critically insufficient. Having experienced the shock of low oil prices in 2009, the UAE designated water as ‘Blue Gold’ and desalination technology as its next-generation growth engine. The only solution to its water scarcity was to convert the seawater from the adjacent Arabian Gulf.

The Mirfa Independent Water and Power Plant, completed by Hyundai E&C in 2017, is a mega-scale infrastructure facility built on a 2.18 million m² site. It features a 1600 MW thermal power plant and a large-scale desalination facility capable of producing approximately 200,000 tons (200 million liters) of fresh water per day. The desalinated water produced here accounts for about 10% of Abu Dhabi's total demand* and is being used not only for domestic purposes but also for large-scale green space creation, fostering Abu Dhabi's development into a ‘Water Hub.’ Notably, this plant is a massive facility that combines two desalination methods: Reverse Osmosis (RO) and Multi-Stage Flash (MSF). MSF is a technique that has been widely used in the Middle East for decades, obtaining fresh water by cooling the steam generated from heating seawater. The newly introduced RO technology removes salt by passing seawater through a membrane at high pressure, offering the significant advantage of much lower energy consumption compared to MSF.

The Mirfa project is replete with special significance for both the UAE and Hyundai E&C. For the UAE, it has become a crucial foundation for meeting the demands of a rapidly growing population and industry, contributing to solving the desert city's water scarcity and building sustainable urban infrastructure. For Hyundai E&C, it represents the fruition of its water industry projects pursued since 2009 and is the first successful example in the Middle East of a complex model that involves the simultaneous construction of both a power plant and a desalination facility. Seawater has now become the energy that lights up Abu Dhabi and the precious water of life that nurtures green spaces throughout the city.

*Calculated based on a population of 3.8 million people and a per capita water consumption of 550L/day.

[Source: KOTRA, UAE Government Portal]

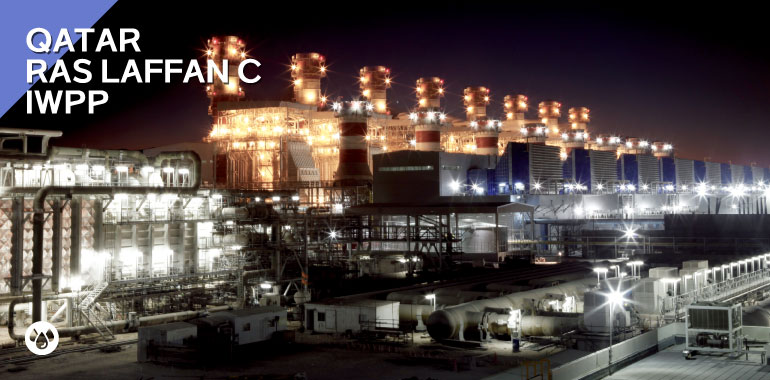

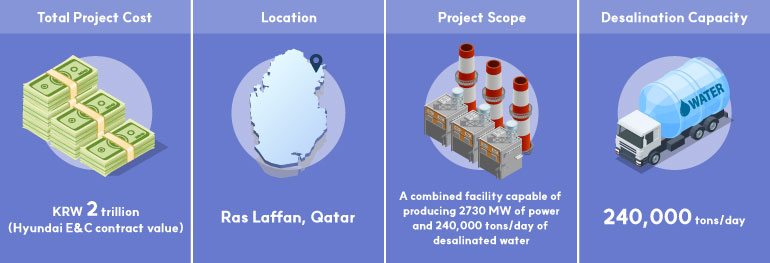

Qatar Ras Laffan C IWPP

Embracing Two Forms of Life: Energy and Water

In the early 21st century, Qatar, which was rapidly growing through natural gas exports, faced a new challenge. It simultaneously needed a stable supply of power to support its industrial development and a secure source of drinking water for its growing population. For a desert nation with no dams or rivers, addressing energy and water needs separately proved inefficient. Qatar required a groundbreaking infrastructure solution that could solve both problems in an integrated manner.

The Ras Laffan C Independent Water and Power Plant (IWPP) was the key project pursued to address this national challenge. In 2008, Hyundai E&C beat out leading global construction companies to secure this project and, in 2011, completed what was then Qatar's largest Independent Water and Power Plant. This facility operates using a Multi-Stage Flash (MSF) desalination method, generating electricity with natural gas as fuel and using the steam produced during power generation to convert seawater into fresh water. The electricity generated is comparable to that of Korea's Shin-Kori Nuclear Power Plant (NPP) Units 3 & 4, and the plant produces approximately 240,000 tons (240 million liters) of desalinated water per day.

The site is broadly divided into a power generation block and a desalinated water generation block. In the power generation block, gas turbines and steam turbines are combined to generate large volumes of electricity on a stable basis. In the water generation block, the high-temperature steam from the power generation process is used to desalinate seawater. The desalinated water then undergoes post-treatment processes such as pH adjustment, mineralization, and disinfection before being stored in a massive reservoir the size of two soccer fields combined. The clean water produced is then distributed throughout Qatar via a national water network. The heat from natural gas and the water of the Arabian Gulf have been reborn as the water of life that sustains Qatar's industries and cities.

Indonesia Peusangan Hydroelectric Power Plant

River Water, Flowing Down Steps and Reborn as Clean Electricity

Although Indonesia is endowed with a rich natural environment, some regions still suffer from unstable power supplies and lack even basic electrical infrastructure. While the demand for electricity has soared due to rapid economic and population growth, reliance on fossil fuels has exacerbated environmental burdens. The development of alternative power sources was imperative to meet the surging demand for electricity while preserving the environment and achieving sustainable development.

Hyundai E&C is on track to successfully complete the construction of the Peusangan Hydroelectric Power Plant project in Indonesia's Aceh province. This hydropower plant utilizes a terraced, or cascade-style, structure to channel river water for power generation, making full use of Indonesia's unique topography and natural conditions.

The Peusangan Hydroelectric Power Plant has a total installed capacity of 88MW and can generate approximately 327 million kWh of electricity annually. This power will ensure stable supplies of power to over 80,000 households in the northwestern Aceh and North Sumatra regions of Indonesia, helping to alleviate local power shortages and stimulate the regional economy.

This is a large-scale, complex project that harmonizes high-difficulty civil and plant engineering, including a 10.8-kilometer water transfer tunnel, upstream and downstream waterways, surface and underground powerhouses, and transmission and substation systems. Hyundai E&C is proceeding with construction on a timely basis, overcoming challenging geological and environmental conditions with state-of-the-art construction technology and global partnerships.

Hyundai E&C’s global water projects go beyond mere water management technology; they offer fundamental solutions to the climate change and resource crises facing humanity. Based on the unrivaled technological prowess and know-how accumulated in the global construction market for over 40 years, Hyundai E&C stands at the forefront of changing the future of nations and cities where water is in high demand.